Table of Contents

SLA (Stereolithography) 3D printing technology is widely known for its incredible precision, but when it comes to heat resistance, traditional resin may fall short. Understanding this limitation is key for industries that require high-performance materials. Fortunately, 3D ceramic printing offers a robust alternative to resin, ensuring heat resistance and durability for demanding applications.

Resin in SLA 3D Printing and Its Heat Resistance Limitations

SLA printing, powered by photopolymer resins, delivers exceptional detail and smooth surface finishes, making it the go-to choice for rapid prototyping, artistic pieces, and low-volume production. However, resin materials typically do not have strong heat resistance. Most resins used in SLA printing have a heat deflection temperature (HDT) of only 50°C to 100°C, meaning they can start to soften or deform under moderate thermal stress. For many industries, such as automotive or aerospace, this can be a significant drawback when producing functional parts that must withstand high temperatures.

Although standard resins are adequate for creating models, mock-ups, and prototypes that don’t require heat endurance, they are not suitable for production environments where the final part will experience elevated temperatures. SoonSer’s SLA printers, designed for high-precision applications, offer a variety of resins suited for different needs, but for users seeking better heat resistance, 3D ceramic printing is a superior option.

The Advantages of 3D Ceramic Printing for Heat-Resistant Applications

For industries that require parts capable of enduring extreme conditions, 3D ceramic printing provides an ideal solution. Ceramic materials such as alumina, zirconia, and silicon carbide offer superior heat resistance, durability, and chemical stability, making them perfect for high-temperature applications. Unlike resins, ceramics can withstand temperatures above 1000°C without degrading, making them essential for aerospace, automotive, and industrial applications.

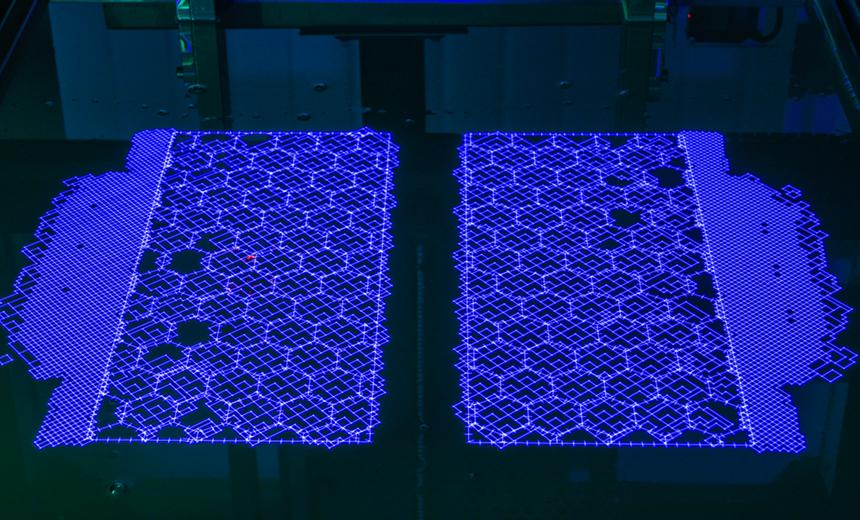

SoonSer’s 3D ceramic printers are built to handle ceramic slurries, enabling the production of complex, high-performance ceramic parts. The SLA ceramic 3D printing process works by curing a ceramic-loaded resin under UV light, then debinding and sintering the part to remove the resin and densify the ceramic material. This process results in high-precision, heat-resistant components that can perform in harsh environments where traditional resins would fail. The ability to print ceramic parts with SoonSer’s 3D ceramic printer allows users to create intricate designs and geometries that would be difficult, if not impossible, to achieve using conventional manufacturing methods. Whether it’s heat exchangers, turbine blades, or high-performance medical implants, SLA ceramic 3D printing ensures consistent and reliable results.

Why SoonSer’s 3D Ceramic Printers Lead the Market

SoonSer has established itself as a leader in the 3D printing industry, particularly with its 3D ceramic printers that are optimized for both performance and versatility. What sets SoonSer’s ceramic 3D printers apart is their ability to handle a range of advanced ceramic materials, offering industries the flexibility to print high-quality ceramic parts with ease. These printers are designed with precision mechanics and robust software integration, ensuring smooth printing and minimal defects, even for complex geometries. With 3D ceramic printing, manufacturers gain a significant advantage by reducing the need for traditional ceramic casting, which can be time-consuming and costly.

SoonSer’s SLA ceramic 3D printing technology offers a faster, more cost-effective solution by producing highly accurate parts directly from digital files. This capability enables industries to move from prototyping to functional production in a fraction of the time, without compromising on material strength or heat resistance. The precision and reliability of SoonSer’s 3D ceramic printers help businesses streamline their production workflows, reduce lead times, and maintain quality control. With a strong track record of success across a variety of sectors—such as aerospace, automotive, medical, and fine arts—SoonSer continues to empower industries with advanced solutions that drive efficiency, innovation, and cost-effectiveness.

Expanding Application Possibilities with SoonSer’s 3D Ceramic Printers

The versatility of SoonSer’s 3D ceramic printers extends beyond just heat resistance. Their machines can handle intricate ceramic designs that are difficult to manufacture using traditional methods. Artists, manufacturers, and engineers alike can take advantage of SLA ceramic printing to create functional prototypes, end-use parts, and artistic models that require exceptional detail and durability.

For industries such as aerospace and automotive, the ability to produce heat-resistant, lightweight parts with complex internal structures offers unprecedented design freedom. SLA ceramic 3D printing also enables the production of medical devices that require both high performance and biocompatibility. For artistic industries, the combination of precision and material quality allows designers to create stunning, one-of-a-kind ceramic pieces that maintain both aesthetic appeal and structural integrity.

Conclusion

As industries continue to push the boundaries of design and manufacturing, the limitations of traditional resin-based 3D printing become more evident, particularly in applications requiring heat resistance. With SoonSer’s 3D ceramic printers, businesses can take advantage of SLA ceramic printing technology to produce high-performance parts that can withstand extreme temperatures. Whether for aerospace, automotive, medical, or creative industries, 3D ceramic printing offers unparalleled precision, reliability, and heat resistance, making it an invaluable tool for innovation and production.