The commissioning of lithium battery assembly lines is a critical step in ensuring their successful operation within the battery manufacturing industry. However, several common mistakes can hinder efficiency and output quality. Identifying and addressing these issues are essential for manufacturers aiming to optimize their battery manufacturing equipment.

Overlooking Equipment Compatibility

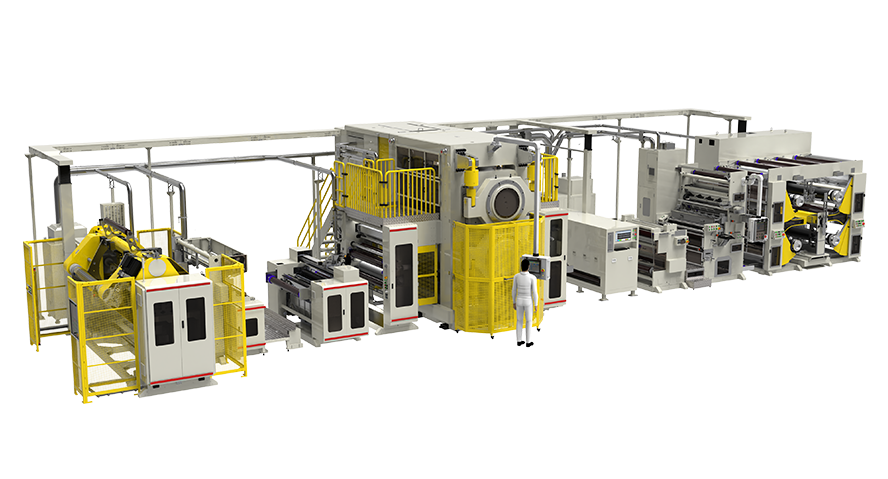

One frequent mistake during commissioning involves overlooking the compatibility of various battery manufacturing equipment components. When integrating different machines, such as calendering and slitting integrated machines, it is crucial to ensure they work cohesively. For example, if the high-speed machine, capable of automatic rewinding and unwinding, is not compatible with other equipment in terms of speed and operation, bottlenecks can occur. This oversight can lead to production delays and increased costs, negatively impacting overall efficiency.

Inadequate Training for Operators

The success of any lithium battery assembly line heavily relies on the expertise of its operators. A common mistake is providing inadequate training on battery production equipment. Without proper training, operators may struggle to handle the machinery effectively, leading to increased downtime and errors. Comprehensive training programs that cover the operation, maintenance, and troubleshooting of each piece of equipment—including those with high production speeds, such as machines capable of operating at 120m/min—are essential for maximizing productivity.

Insufficient Testing and Quality Control

Another crucial oversight relates to the lack of thorough testing and quality control prior to full-scale production. Failing to implement rigorous testing protocols during the commissioning phase can result in unforeseen issues that affect battery quality. For instance, if the roller surface width is not correctly calibrated or inspected before mass production, it may lead to inconsistencies in the final product. Establishing robust quality control processes ensures that all equipment functions optimally and meets industry standards.

Achieving Success with Yinghe’s Expertise

Common commissioning mistakes can severely impact the efficiency of lithium battery assembly lines if left unaddressed. By focusing on equipment compatibility, operator training, and thorough testing, manufacturers can greatly enhance their battery production equipment’s performance. Companies like Yinghe specialize in high-quality battery manufacturing equipment, including advanced calendering and slitting integrated machines that streamline the production process. Partnering with Yinghe enables manufacturers to sidestep these commissioning pitfalls and achieve success in the competitive landscape of battery manufacturing.