Table of Contents

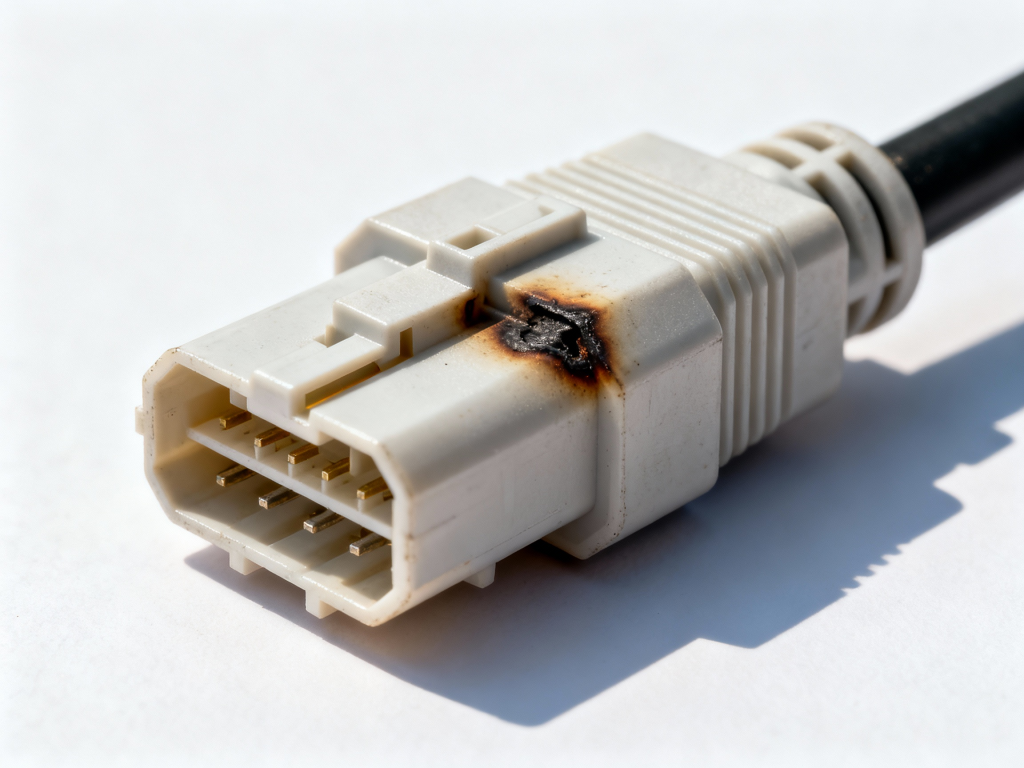

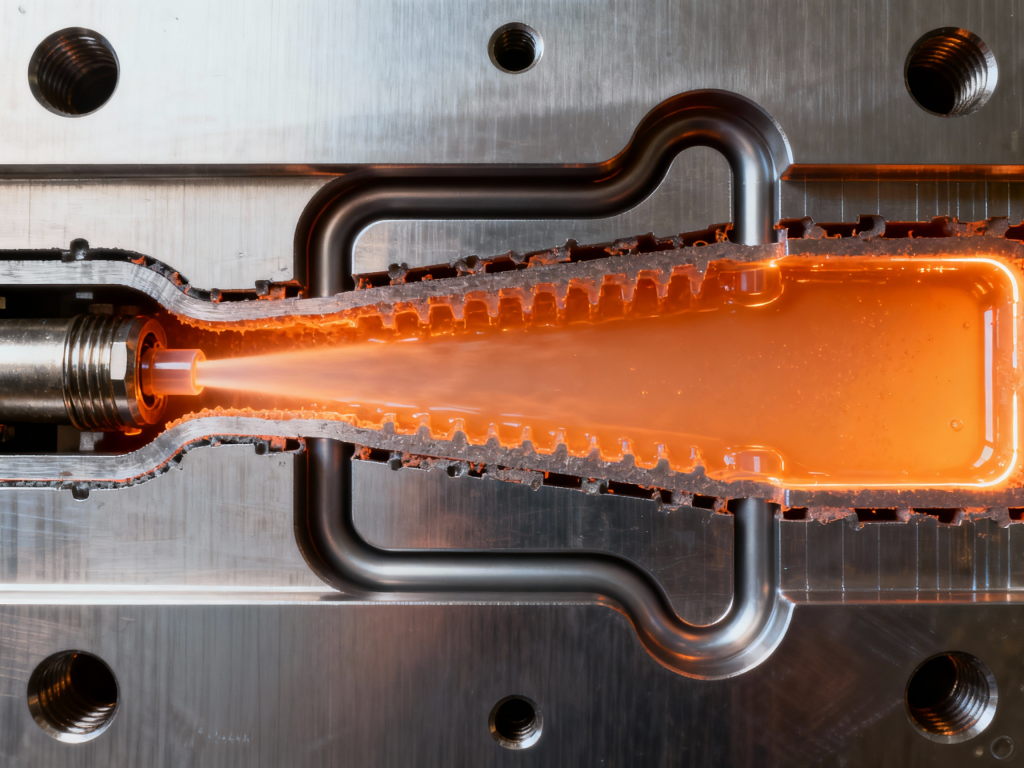

The “diesel effect”—a phenomenon where trapped air ignites under high pressure—remains a critical failure mode in manufacturing complex connector housings. When air cannot escape the mold cavity during the high-velocity filling phase, it undergoes adiabatic compression, spiking temperatures above the resin’s auto-ignition point. This results in carbonized burn marks and structural degradation, compromising the dielectric performance of sensitive electronic components. For engineers sourcing plastic injection molding china, understanding the interplay between venting geometry, material viscosity, and injection speed is paramount to achieving zero-defect production.

Strategic Venting Architectures for High-Precision Connector Housings

Effective venting is not merely about adding gaps; it requires a calculated engineering approach tailored to the specific rheology of the polymer. By positioning vents at known flow fronts and utilizing advanced insert technologies, manufacturers can neutralize gas traps in intricate unscrewing or multi-cavity molds.

Optimizing Vent Depths and Geometry

The depth of the primary vent is the single most critical dimension in preventing diesel effect burns without causing flash. This dimension must strictly correlate with the material’s viscosity index. For crystalline resins like PA66 or PBT, often used in connectors for their thermal stability, the vent depth must be machined between 0.01 mm and 0.02 mm. Deeper vents would allow the low-viscosity melt to escape, forming flash. Conversely, amorphous materials like PC or ABS require slightly deeper channels, typically 0.03 mm to 0.05 mm, to accommodate their higher viscosity.

Beyond depth, the “land length”—the distance from the cavity edge to the deeper relief channel—must be minimized to reducing airflow resistance. A land length of 0.8 mm to 1.0 mm is optimal. If the land is too long, backpressure builds up, triggering the diesel effect despite the presence of a vent. Leading precision plastic injection molding china facilities utilize EDM (Electrical Discharge Machining) to achieve these micro-tolerances, ensuring the vent allows gas evacuation while effectively sealing the molten plastic.

Advanced Solutions for Blind Spots and Deep Ribs

Connector housings often feature deep ribs or blind holes where standard parting-line venting is impossible. In these scenarios, gas accumulates at the bottom of the feature, causing short shots or burns. Advanced molders integrate porous steel inserts (sintered metal) which allow gas to permeate through the steel structure itself while blocking the plastic melt. Alternatively, active vacuum extraction systems can be synchronized with the injection cycle to mechanically draw air out of the cavity milliseconds before the melt arrives. Data from automotive connector production lines indicates that vacuum-assisted venting can reduce rejection rates due to burn marks by over 85% in complex geometries.

Advanced Process Control in Plastic Injection Molding Service China

While mold design provides the escape route for gas, process parameters dictate the volume and velocity of the air being displaced. precise calibration of the injection unit is essential to prevent overwhelming the venting capacity.

Regulating Injection Speed and Clamping Force

To mitigate adiabatic compression, engineers must implement multi-stage injection profiles. By programming a high-speed fill for the bulk of the part and decelerating significantly as the melt front approaches the venting areas (end-of-fill), the air is given sufficient time to evacuate without compressing to the point of ignition. For example, reducing the final 5% of the shot size to 10-15% of maximum speed can eliminate burns in unscrewing plastic injection molding china applications where thread geometries create multiple gas traps. Additionally, clamping force must be optimized; excessive tonnage can deform the mold plates, crushing delicate vent channels and rendering them ineffective. A reduction in clamp force by 10-15% below the maximum rated capacity often improves venting performance without causing flash.

Maintenance Protocols for Vent Longevity

Venting channels are prone to clogging with release agents, dust, and polymer residue (plate-out). A clogged vent functions like a sealed wall, immediately reintroducing the diesel effect. China custom plastic injection molding suppliers enforce strict preventive maintenance schedules. Micro-cleaning of vents should occur every 20,000 to 50,000 cycles, depending on the material’s outgassing properties. Ultrasonic cleaning baths are effective for removing deposits from porous inserts without damaging their structure. Regular inspection of parting lines for wear is also crucial, as rounded edges can alter the effective vent depth, leading to flash or burns.

Livepoint Tooling: Integrated Solutions for Critical Connector Molding

Livepoint Tooling stands as a premier partner for global OEMs requiring high-reliability connector housings and technical components. With over 23 years of expertise in the plastic injection molding service china sector, the company specializes in overcoming complex molding challenges through rigorous engineering and advanced tooling capabilities.

Precision Tooling and Industry Certification

Livepoint Tooling operates a state-of-the-art facility certified to ISO 9001 and IATF 16949 standards, ensuring compliance with the stringent quality requirements of the automotive and medical industries. The company’s tooling division is capable of machining molds with tolerances as tight as ±0.01 mm, a critical factor for successful venting in miniaturized connector designs. Their portfolio includes high-cavitation molds and complex unscrewing molds that maintain structural integrity over millions of cycles.

Comprehensive Manufacturing Capabilities

From rapid prototyping to mass production, Livepoint Tooling offers a vertical solution. Their expertise extends to 2K (two-shot) molding and insert molding, allowing for the seamless integration of seals and metal contacts within the connector housing. By leveraging advanced Moldflow simulation and scientific molding principles, Livepoint Tooling predicts gas trap locations during the design phase, eliminating diesel effect risks before steel is cut. With their extensive manufacturing experience, they are able to provide consistently high-quality products for demanding applications.

Conclusion

Eliminating diesel effect defects requires a synergy of precise mold engineering and disciplined process control. Contact the engineering team at Livepoint Tooling today to audit your connector designs and secure a high-precision manufacturing partner for your next project.