Table of Contents

The demand for high-performance components across sectors like aerospace, medical devices, and new energy vehicles has placed immense pressure on modern machine shops. Achieving micron-level accuracy while maintaining cost-efficiency is no longer just an advantage—it is a survival requirement. For professionals navigating these complexities, the China machine tool exhibition 2026, also known as ITES China, serves as a critical bridge between theoretical engineering and practical floor-shop solutions.

By attending such large-scale events, manufacturers can directly observe how emerging technologies tackle the most persistent bottlenecks in the industry.

Overcoming Material Instability and Precision Drifts

One of the primary hurdles in precision manufacturing is managing the behavior of advanced materials. Hardened alloys and composites often cause rapid tool wear or thermal deformation, leading to dimensional inaccuracies. At machine tool shows 2026, the focus is shifting toward “embodied intelligence” and real-time monitoring.

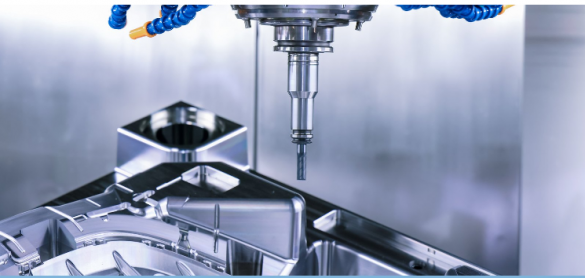

Exhibitors at ITES China demonstrate CNC systems equipped with advanced thermal compensation and vibration dampening. Instead of relying on manual adjustments, these machines use sensors to detect minute changes in temperature or spindle load, making automatic corrections during the cutting process. This evolution ensures that even a 2-micron precision requirement, common in automotive connector stamping or medical implant production, remains consistent throughout high-volume runs.

Tackling Complex Geometries with 5-Axis Innovation

As designs become more intricate—think of the thousands of micropores on a high-end shower head or the complex cooling channels in AI server plates—traditional 3-axis machining often hits a wall. The cost of multiple setups and the risk of alignment errors can derail a project.

The China machine tool exhibition 2026 provides a venue to explore the latest 5-axis machining centers that eliminate these bottlenecks. By allowing the tool to approach the workpiece from any angle in a single setup, these machines reduce handling time and significantly improve surface finish quality. Visitors can witness live demonstrations of these units handling “undercuts” and deep-cavity milling that were previously considered impossible or prohibitively expensive to produce.

Bridging the Labor and Efficiency Gap

Beyond the technical specifications of the hardware, the manufacturing sector faces a significant shortage of skilled operators. This human element is a challenge that machine tool shows 2026 address via integrated automation and robotics.

At the upcoming ITES China event, scheduled for March 31 to April 3, 2026, at the Shenzhen World Exhibition & Convention Center, the focus will be on “plug-and-play” automation. From robotic loading arms to AI-driven inspection systems, these solutions allow machine shops to maintain 24/7 “lights-out” manufacturing. By automating the repetitive tasks of loading, unloading, and quality checking, companies can redirect their skilled workforce toward more complex programming and process optimization tasks.

Why ITES China 2026 is the Essential Hub

With over 160,000 square meters of exhibition space and more than 1,500 exhibitors, ITES China stands as a premier platform for sourcing and technical exchange. It is not merely a display of hardware but a comprehensive ecosystem covering:

- Metal Cutting: High-end CNC machines and precision tools.

- Robotics: Intelligent manufacturing and industrial control technology.

- Precision Components: OEM/ODM manufacturing and specialized testing instruments.

By engaging with original equipment manufacturers and industry experts, attendees gain first-hand insights into how to integrate additive and subtractive manufacturing or how to implement digital twin technology to predict machining outcomes.

Finding Solutions for the Future

The path to higher productivity and lower operational costs is rarely found in a catalog alone. It requires seeing the machines in motion and discussing specific production hurdles with the engineers who design the equipment. Whether you are struggling with the straightness of deep holes or the stability of thin-walled structures, the China machine tool exhibition 2026 offers the specialized knowledge and technological tools needed to turn these challenges into competitive advantages. Participating in this flagship event ensures your operations remain at the forefront of the global manufacturing landscape.