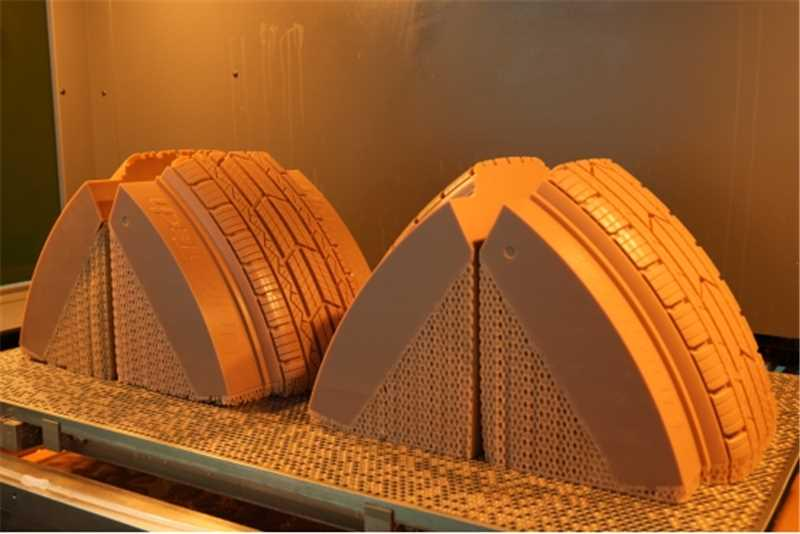

Additive manufacturing has revolutionized the way industries create complex parts, especially in sectors such as tire mould production. In particular, SLA 3D printers offer a significant advantage when it comes to the high precision needed for tire moulds. The choice of materials used in 3D printing for tire moulds plays a pivotal role in the efficiency, durability, and accuracy of the final product.

Understanding the Importance of Material Selection in SLA 3D Printing

In SLA 3D printing, the materials used must meet several criteria, including high durability, precise resolution, and the ability to withstand the stresses of real-world applications. For tire mould production, the material needs to replicate the intricate designs while maintaining strength and dimensional stability. UnionTech, an industrial 3D printer manufacturer, offers a variety of resin options for these precise tasks, ensuring that tire moulds are manufactured with the utmost accuracy.

Common Materials for SLA 3D Printing in Tire Mold Manufacturing

SLA printing typically uses photopolymer resins, which solidify under UV light to form durable, high-precision parts. These resins can be categorized into different types based on their specific properties. For tire mould production, UnionTech’s SLA 3D printers utilize specially engineered resins that cater to the tire industry’s requirements, offering a fine balance of strength and flexibility. These materials provide high resolution, which is necessary for creating moulds that capture every detail of tire patterns.

Advancements in Resin Technology for Tire Mold Manufacturing

Material advancements have significantly contributed to the development of tire moulds via SLA 3D printers. New resin formulations allow for quicker curing times, reducing production cycles. These materials also offer improved resistance to wear and heat, critical factors when designing tire molds for real-world applications. As an industrial 3D printer manufacturer, UnionTech is continually improving its range of materials to accommodate the growing demands of industries such as tire mould production.

Conclusion

The choice of materials in SLA 3D printing for tire mould impacts the final product’s performance and quality. For industries like tire mould manufacturing, it is essential to use high-quality, specialized materials to achieve the required precision and durability. With UnionTech’s advanced resin technology, companies can ensure the production of tire moulds that meet both the design and functional requirements, paving the way for more efficient manufacturing processes in the future.