Efficient and precise sorting is a critical part of modern food processing. WEIGHT SORTING provides solutions that integrate intelligent technology to maintain high standards across production lines. Their equipment ensures that defective, misformed, or mislabeled products are efficiently removed, supporting food safety and consistency. The implementation of a sorter machine allows factories to minimize waste and streamline operations without compromising on quality.

Intelligent Features for Consistent Results

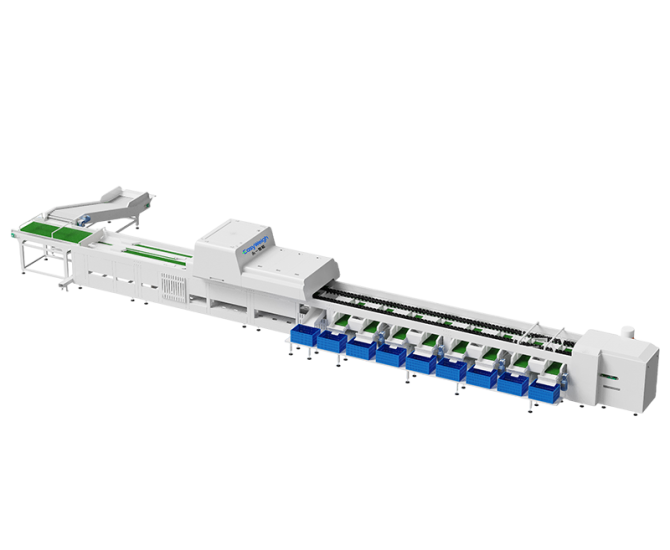

The Optical Sorting Machine offered by WEIGHT SORTING utilizes advanced imaging systems combined with intelligent algorithms to analyze each item. By detecting color, size, shape, and surface defects, the sorter machine ensures that only products meeting strict quality standards move forward. Additionally, it can identify labeling or coding inconsistencies, allowing manufacturers to maintain compliance with industry regulations. These intelligent features reduce manual inspection requirements and improve overall operational efficiency.

Adaptability Across Various Food Processing Applications

One of the advantages of their systems is versatility. The Optical Sorter is suitable for different food categories, including fruits, vegetables, snacks, and processed goods. Its customizable settings enable operators to adjust sorting parameters according to product specifications. By automating this process, WEIGHT SORTING ensures that production lines run smoothly while maintaining consistent output. The sorter machine also contributes to reducing labor-intensive processes, allowing staff to focus on other critical tasks within the facility.

Driving Efficiency and Minimizing Waste

By integrating an optical sorter machine into production, companies can achieve more predictable outcomes. These sorter machines efficiently reject substandard items, preventing them from reaching consumers and protecting brand reputation. WEIGHT SORTING emphasizes intuitive controls, making it easier for operators to manage the process with minimal training. Overall, the sorter machine supports both quality assurance and productivity goals, offering a practical solution for food processors seeking to optimize their workflows.